What goes up – must come down

The laws of gravity apply to your Supply Chains too

Not too long ago, there was angst and handwringing over questions such as:

How much should I buy and store for Just in Case?

How many times should I purchase raw materials for the same orders?

Today, we hear both Target and Walmart, among others, state that they have too much inventory.

Not a surprise for supply chain professionals, but perhaps a reminder about the laws of gravity.

What goes up, must come down.

In the panic over potential loss of customers, supply chains overpurchased raw materials. This in part caused supply chain blockages – only so much raw material can fit into a supply chain pipeline. When everyone is panic buying and purchasing “Just in Case” and “Just Get Me Something” extra orders, the pipeline becomes clogged with all the extra inventory that your company, as well as all the other panicked Corporate buyers, is now on the hook to pay for, even if you received another supplier’s raw material earlier for that newly delivered order.

This is the “what goes up” part.

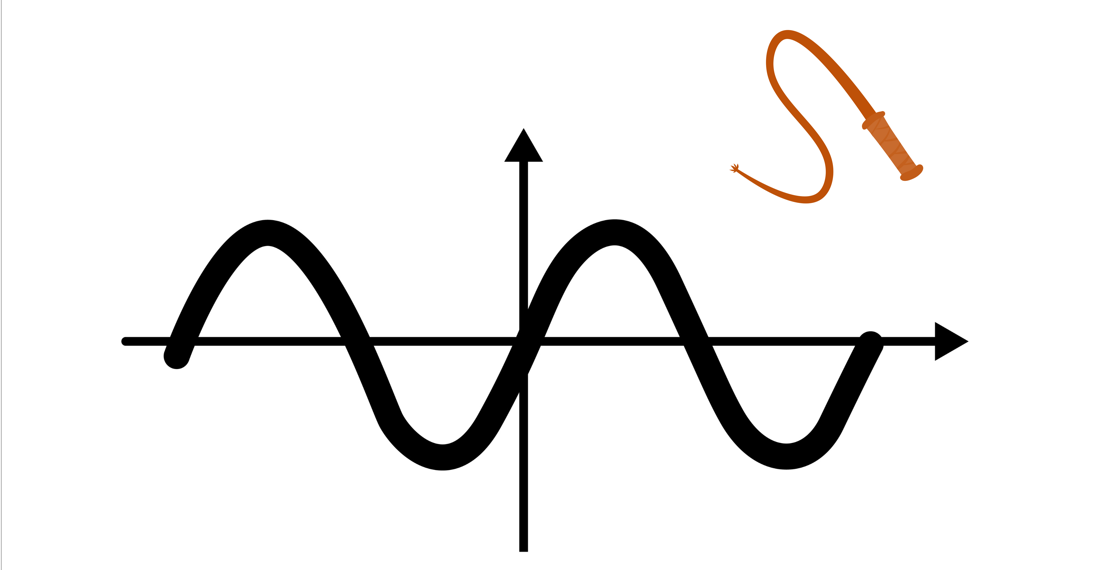

For those who have experienced or learned about the Bullwhip Effect previously, the above is no surprise.

Still, due to enabling the Bullwhip Effect, we now have too much inventory which has decreased cash reserves, increased excess inventory, and expanded warehousing and inventory control requirements.

And here’s the new problem; now you need to get rid of inventory.

Even if that means putting inventory on sale to reduce the excess. Even if that means not purchasing more raw materials or finished goods until your inventory levels get back to something considered more normal.

This is the “what goes down” part.

Severe reductions in raw material/finished goods orders. Pricing swings. Layoffs due to lower demand.

But perhaps you were not familiar with the Bullwhip Effect.

My hope by writing this article is that if you’ve never heard of the Bullwhip Effect because your company or your training has not provided known supply chain practices, you now have heard about it and have a baseline understanding. If you do understand it, my hope is that you share your knowledge with those who do not to help eliminate future panic and clogged supply chains.

Why?

Because what goes down also goes back up.

The classic Bullwhip Effect means that we lurch from too much to too little inventory in cycles.

The discipline and understanding surrounding the taming of this effect was created prior to 2000 by Proctor and Gamble. P&G had to answer why diaper orders were whipsawing when babies were consistent in their use of diapers and P&G was able to get data on how many babies needed diapers where.

We have been experiencing similar problems, though maybe not in diapers for your supply chains. And the same discipline of not panicking is still needed.

Yes, demand was erratic, but how much of it was due to your customer’s panicking?

Your answer to that question provides insight into what is negotiable now, in today’s “lower” demand environment. End-to-end supply chain communication is key.

Strategic sourcing takes advantage of what we can do now to smooth the rough spots both now and in the future.

But first, you need to know what you are really dealing with.

Panic is something we can deal with. The great thing about it is that while calmly dealing with our customer’s panic, you burnish your image as the supplier of merit during your customer’s tough times.

Disciplined analysis of what your customers will need for their customers over time helps create realistic strategy that in turn helps your supply base negotiations and data exchange.

In return, you’ll save money, keep critical relationships, get raw material secured, and eliminate much of the chaos of dealing with excess inventory and warehouse overload.

You’ll be the calm compared to the roller coaster ride of everyone else’s Bullwhip.

Key words and concepts: Bullwhip effect; supply chain strategy; strategic sourcing; inventory control; supply chain training; Cynthia Kalina-Kaminsky; Process & Strategy Solutions; SCOR

Cynthia Kalina-Kaminsky helps companies of all sizes successfully avoid panic attacks that ruin your customer performance. Together you transform supply chains, integrate digital technology solutions, and embed sustainability. Learn more here: SCOR advanced supply chain training – FREE bonus session.

Comments