On the 12th Day of Christmas my supply chain gave to me…

… 12 integrations

(It’s officially the last Day of Christmas – Jan 5)

I started as a manufacturing engineer designing assembly lines, inventory flows, and machinery to make or test product, automating the factory to increase global competitiveness, and working with amazing people producing quality product.

Manufacturing was the supply chain (although the phrase supply chain didn’t exist then).

Now, it’s a component to maneuver.

Not being “The supply chain” was a tough lesson to learn, but now I understand just how valuable that adjustability is. Especially in today’s rapidly changing economies and political environments.

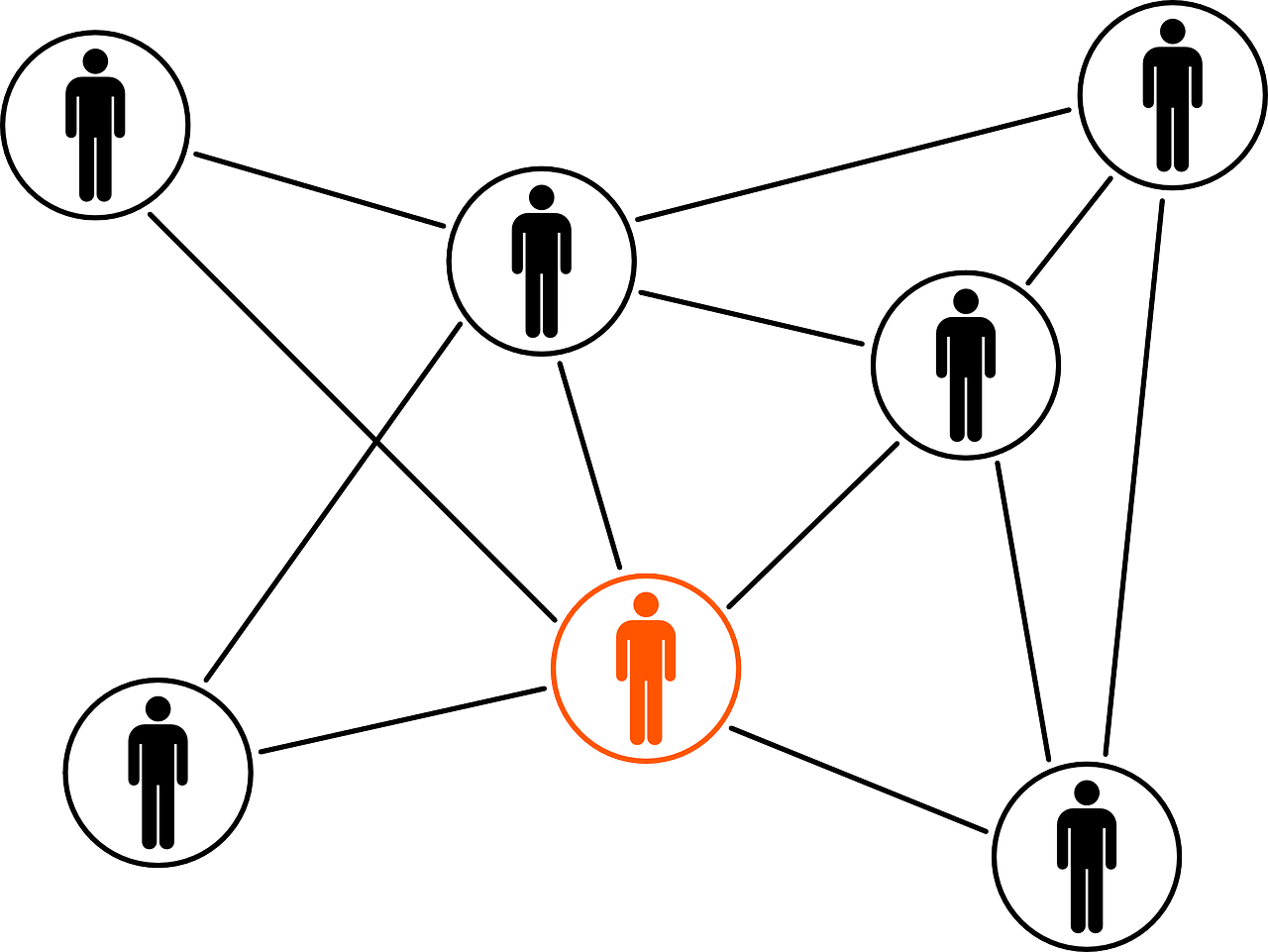

To be agile enough, fast enough, good enough, supply chains must be built recognizing that there are segments to the whole.

Segments that can be networked together and unnetworked as needed.

It’s more than just Supplier A is not able to handle the volume so let’s bring in Supplier B to help, although that is still important.

It’s understanding when using a specific partner (whether raw material supplier, contract manufacturer, your manufacturing, 3PL, or outside repair sites) or set of partners needs to be inserted into a supply chain to

- avoid risk and keep the supply chain moving,

- add local uniqueness to a standard product or service,

- engage new customers, etc.

Building an agile and successful network is more than just volume and more than just efficiency. You adjust your network’s supply chain segments to gain a strategic advantage you need must execute.

This adds more complexity to your supply chains. Yet it also gives you more to play with when needed.

To make sure you’re not adjusting segments that don’t need to be adjusted, simulations are extremely helpful.

Review your strategic risk during network adjustment, too.

AI may help identify what is happening where (ie: provide an early warning signal) so that segments can be adjusted in a timely manner.

However, there is a big risk you need to be aware of.

If the segments are not aligned in their performance strategy and governance (ie: framework), they will not play together nicely. That will cost you in performance and customer satisfaction.

It is imperative that all segments, those you own and those you partner with, understand the performance strategy and metrics that must be met ahead of time and can perform competently to them.

This is one of the advantages that I’ve had using SCOR, the Supply Chain Operations Reference model. It standardizes and ties together processes, people, metrics, and practices. When you take each individual standardized piece and choose to connect it up and operate it in a unique way, you built in competitive advantage that others can’t copy. You have organized segments that you can easily integrate to enable faster network adjustment and to meet new and changing requirements.

#supplychain #network #segmentation #performance #supplychainperformance #metrics #supplychainmetrics #integration #SCOR #ProcessandStrategy #CynthiaKalinaKaminsky

Thank you for reading my blogs.

Cynthia Kalina-Kaminsky is an ASCM Master SCOR instructor and consultant, and a supply chain professional. With you and your company, she uses SCOR, which includes an Orchestrate process category containing both network design and supply chain segmentation. These are paired with assessments for supply chain innovation, transformation, digital capability building, and sustainable/resilient supply chain performance you and your business can depend on.. Learn more here

Comments